CO2 focus lens

The function of the CO2 laser cutter focusing lens is to focus the laser light on one point, so that the laser energy per unit area reaches a large value, burning the workpiece quickly, and achieving the functions of cutting and engraving.

CO2 laser mirrors

CO2 laser generator is a gas molecular laser, co2 is used as the medium, and the light beam is transmitted through the co2 laser mirror.

Board

Motor

Monitoring device

Border patrol camera on mixed cut

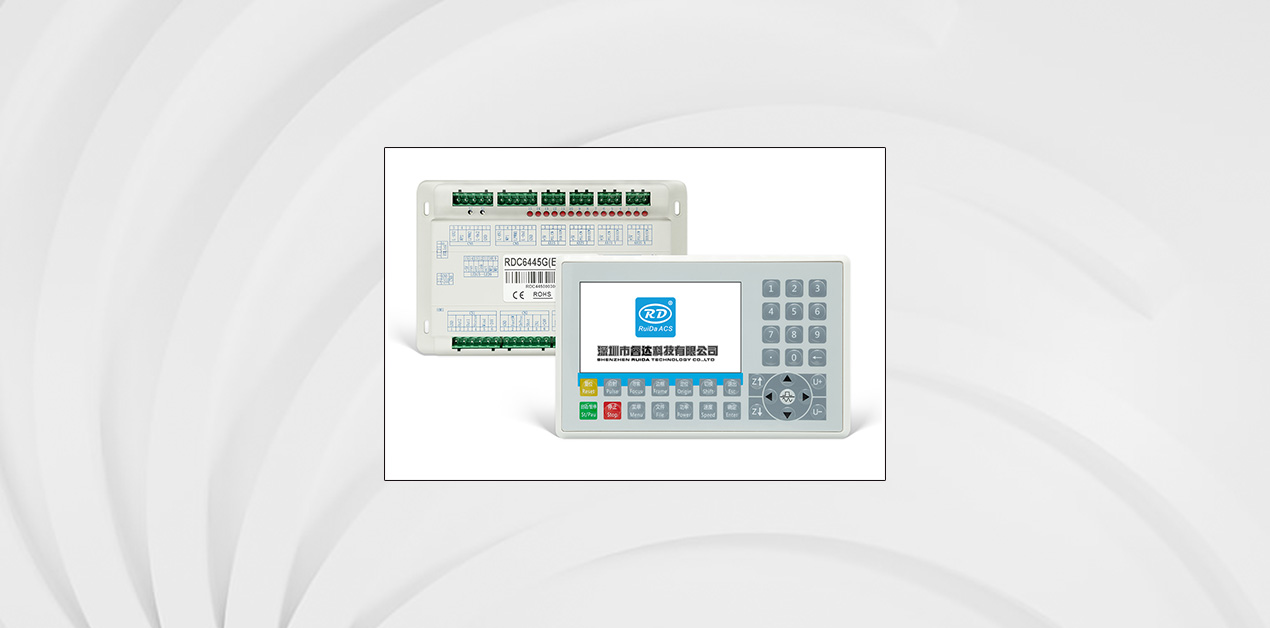

RD6445

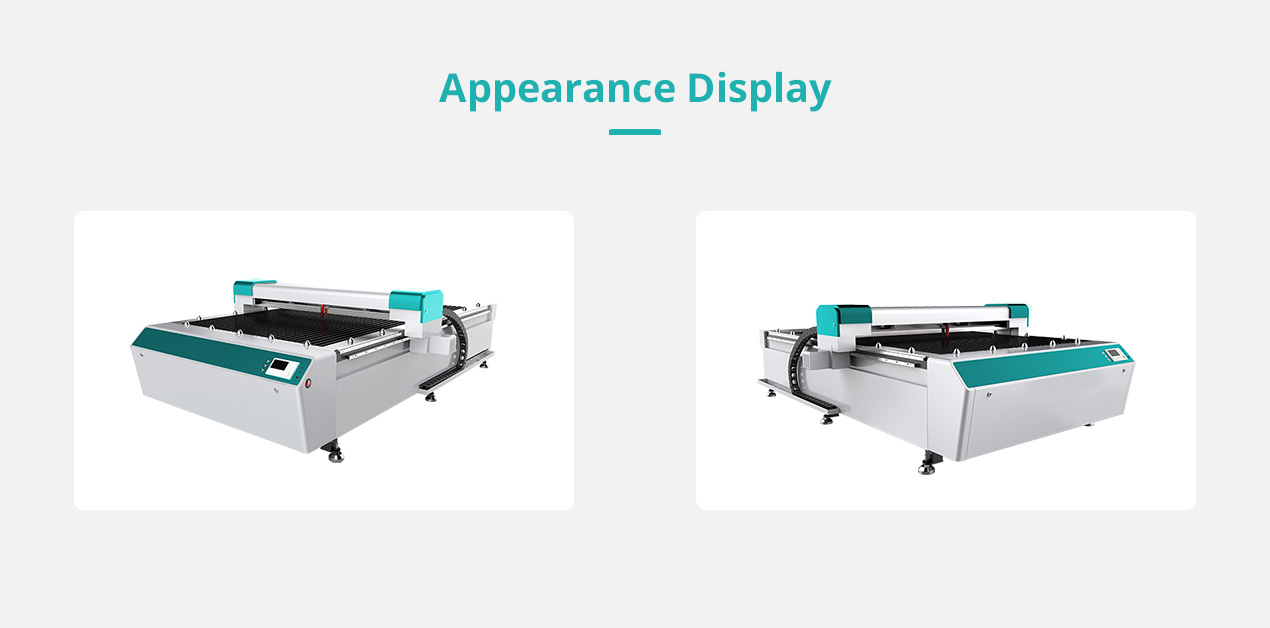

1325-M6 CO2 Laser Cutter Parameter

| Model number | 1325-M6 |

| Working area | 1300*2500 mm |

| Laser tube type | Sealed CO2 glass laser tube |

| Platform type | blade/honeycomb/flat plate (optional depending on material) |

| Feeding height | 30 mm |

| Engraving speed | 1000mm/s |

| Positioning accuracy | 0.01mm |

| Laser tube power | 130-150W |

| Continue working after power outage | √ |

| Data transmission method | Network port USB U disk |

| Software | LaserCAD/RDworks V8 |

| Memory | 128MB |

| Motion control system | Stepper motor drive/hybrid servo motor drive |

| Processing technology | engraving, relief, line drawing, cutting and dotting |

| Supported formats | JPG PNG BMP DXF PLT DSP DWG |

| Supports drawing software | Photoshop AutoCAD CoreLDRAW |

| Computer system | Windows10/8/7 |

| Minimum engraving size | 1*1mm |

| Application materials | Acrylic, wood board, leather, cloth, cardboard, rubber, two-color board, glass, marble and other non-metallic materials |

| Overall dimensions | 3305*2180*1250 |

| Voltage | AC220V/50HZ (voltage can be customized according to country) |

| Rated power | 2600W |

| Total weight | 970KG |

The working principle of the co2 laser machine

Co2 sealed in the laser tube generates a beam through high pressure, which is reflected by the reflector. The condenser focus the beam to a point, and when it is strongest, it is emitted through the laser head.

Co2 laser machines applicable materials

1.Acrylic, wood, leather, cloth, cardboard, rubber, two-color boards, glass, marble and other non-metallic materials;

2.Thin metals: carbon steel, stainless steel.

Co2 laser machine application industries

Advertising, printing and packaging, industrial gifts, leather clothing, molds, kitchen utensils, etc.

Features of co2 laser cutter

1. The frame is precision machined to ensure the optical path and accuracy.

2. The table and the machine tool are separated to solve the problem of machine tool deformation when the low-power cutting machine works for a long time.

3. The table surface is finished, which solves the problem of uneven table surface. The smooth table surface greatly improves the cutting accuracy during work and increases the service life.

4. Hidden transmission structure prevents dust and increases service life.

5. The integrated structure of the copper gear ensures accuracy and corrosion resistance.

6. The isolation board uses fireproof materials to reduce the risk of fire.

7. The material of the transmission part is upgraded from commonly used aluminum profiles to 6063-T5 high-strength aluminum profiles, which reduces the weight of the beam and improves the strength of the beam.

8. Fire protection device to reduce the risk of fire.

Consumable parts

1.Focusing lens: Depends on maintenance, usually replace one lens every three months;

2.Reflective lenses: Depends on maintenance, usually replaced every three months;

3.Laser tube: lifespan is 9,000 hours (In other words, if you use it 8 hours a day, it can last about three years. ), replacement cost depends on power.