Laser cutting machine fiber has occupied the mainstream of the sheet metal processing industry. Various types of cnc fiber laser cutting machine are emerging on the market. Different fiber laser cutting machine metal quality will definitely be different. The most intuitive performance to judge the performance of a hot selling fiber laser cutting machine for metal is to see whether the cutting quality is good or bad.

The following LXSHOW will introduce the basis for determining whether the fiber laser metal cutting machine cutting quality is good or bad.

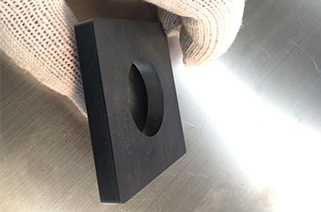

Roughness of cutting section

The section of the workpiece after metal fiber laser cutting machine cutting will have certain lines. Roughness refers to the depth of the lines formed after being cut by cnc laser cutting machines fiber. Roughness has a great influence on the appearance of the work piece. The shallower the line means the better the cutting effect of 3015 fiber laser cutting machine; the deeper the line Means that the fiber laser cutting machine cnc cutting effect is worse.

Cutting section perpendicularity

When the thickness of the sheet metal cut by 1530 fiber laser cutting machine exceeds 10mm, the perpendicularity of the cut edge of the sheet metal becomes an important indicator of the cutting quality of vertical. When the metal sheet fiber laser cutting machine focus is not focused on the sheet metal, the laser beam will become divergent, causing the side deviating from the fiber laser cutting machine for metal cutting head to widen. If the verticality of the cutting edge exceeds, the cutting quality of cnc metal sheet fiber laser cutting machine is better.

Cutting edge texture

When machine fiber laser cutting cuts thick plates at a higher speed, the metal melted by the fiber metal sheet laser cutting machine laser beam will be ejected behind the laser beam, forming curved lines on the cutting edge. Remedy: Reduce the feed rate at the end of the fiber laser cutting machine for stainless steel cut.

Cutting edge burr

Another important factor that affects laser fiber cutting machine cutting quality is burrs. The reason is that removing the burr requires extra work. Therefore, a laser cutting machine metal fiber with good cutting quality will produce very few burrs during cutting.

material deposition

Before desktop fiber laser cutting machine runs, sometimes a layer of oil film is applied. When the manufacturer does not use auxiliary gas, material deposits may form on the surface of the workpiece.

The surface of the workpiece is corroded or dented

When sheet metal fiber laser cutting machine is cutting such workpieces, these places should be avoided as much as possible to avoid from generating large cutting errors.

heat affected zone

When fiber optic laser cutting machine is running, the vicinity of the incision will be heated by the laser, which may cause deformation of the workpiece. The degree of deformation of the workpiece to be processed is also a reference standard for judging the cutting quality of stainless steel fiber laser cutting machine.

Previous:

LXSHOW wait for you in Canton Fair

Previous:

LXSHOW wait for you in Canton Fair