After purchasing the fiber metal sheet laser cutting machine, they do not need to debug the metal sheet fiber laser cutting machine to ensure normal operation. This is also an inspection location, depending on the cutting quality, this is the most direct way to inspect the quality of the equipment. For new customers, when purchasing equipment, they will be asked to look at the diy fiber laser cutting machine proofing first.In addition to the cutting speed of the equipment, the proofing depends on the cutting quality of the sample. Then how to look at the cutting quality, and pay attention to certain aspects. Let me introduce it in detail below.

1. Verticality

When the thickness of the sheet metal exceeds 10mm, the verticality of the cutting edge is very important. When away from the focus, the laser beam becomes divergent, and depending on the position of the focus, the cut becomes wider toward the top or bottom. Mm, the more vertical the edge, the higher the cutting quality.

2. Average

The laser cutting section will form vertical lines. The depth of the lines determines the displacement of the cutting surface. The shallower the lines, the smoother the cut section. It hardly affects the appearance of the edge, but also affects the friction characteristics. In most cases, it is necessary to minimize the maximum, so the shallower the texture, the cutting quality will be fine.

3. Texture

As a result, curved lines are formed on the cutting edge, and the lines closely follow the moving laser beam. When cutting thick plates at high speed, the molten metal will not appear in the tip under the vertical laser beam, but will spray at the rear of the laser beam. come out. In order to correct this problem, reducing the feed rate at the end of the cutting process can greatly eliminate the formation of lines.

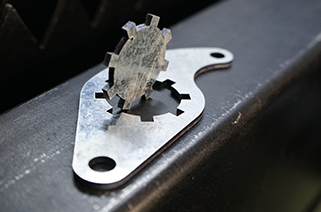

4. Cutting width

The approximate width generally does not affect the cutting quality. The cutting width has an important effect only when a particularly precise contour is formed inside the component. This is because the cutting width determines the minimum inner warp of the contour. When the thickness of the sheet increases, the cutting width is also arbitrary So increase. Therefore, if you want to ensure the same height, no matter how long or wide the workpiece is, the processing area of the fiber laser cutting machine for metal should be constant.