1 Laser cutting head

The Swiss Raytools fiber laser cutting head is used with Z-axis follow-up function. The high-speed sensing cutting head uses capacitive sensing to provide a stable and fast automatic cutting height adjustment. A wide range of nozzle designs are available for a wide range of focal length lenses. Can be equipped with optical lenses of different focal lengths. The focal length and nozzle height can be flexibly adjusted, including X-Y direction lens and nozzle coaxial adjustment.

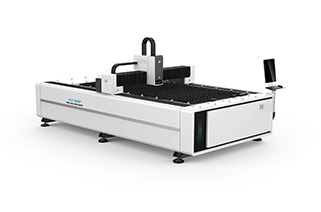

2 The bed

XTC-F1530-6X tube plate integrated laser cutting machine body part is completely independent research and development, the bed base is welded by square tube, processed by large gantry milling machine.

We have many years of processing experience for large machine bed. After each bed is roughed, it will be placed for 30 days to 45 days, and the internal stress will be completely released before finishing to ensure the processing accuracy!

Each factory bed has a guide rail at a distance of 2.5 meters and a parallelism of less than 0.02 mm. With a solid bed, you can guarantee efficient, high-precision cutting speed!

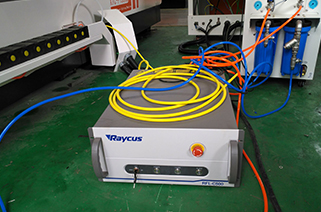

3 Control box

The electrical control box of the fiber laser cutting machine is separately configured to reduce interference and facilitate maintenance.

In order to ensure the stability and reliability of the system and avoid signal interference, the following measures are taken to ensure the electrical process:

1. The main circuit component and the control circuit component layout are divided into blocks and shunted.

2. Use shielded or twisted pair cables for the key control components.

3. The motor is connected to the drive with a separate outlet that is not in parallel with any other wiring.

4. The I/O interface board, controller, and sensor are close to each other.

5. The upper and lower connection lines of the equipment are over-wired and the Weidmuller terminals are excessive.

4 Safety protection system

The laser output from the fiber laser is classified into the fourth level according to the laser classification standard of the American Laser Association. That is, the dangerous laser level has certain damage to the human body. Therefore, the safety protection measures of the whole system are extremely important.

Next:

RFL-1000 series laser 1

Next:

RFL-1000 series laser 1