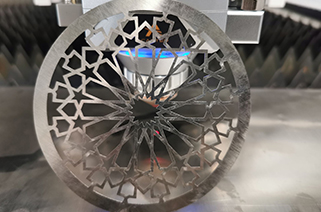

desktop fiber laser cutting machine is the most commonly used processing method in metal processing and manufacturing, which is very different from traditional cutting methods. fiber optic laser cutting machine replaces major industries with a new cutting method.

The following will introduce the reasons for adding auxiliary gas and how to add auxiliary gas to maximize the economic benefits of fiber metal laser cutting machine

The reason why auxiliary gas needs to be added during the fiber laser cutting machine 3015 cutting process:

To know how to choose auxiliary gas for fiber laser cutting machine 1530, you need to understand the effect of auxiliary gas: auxiliary gas can blow away the slag in the slot; cool the workpiece to reduce the deformation caused by the heat-affected zone; cool the focusing lens To prevent dust from entering and polluting the lens; to support combustion.

Advantages of various auxiliary gases

In view of the different cutting materials and the different thickness of the same material, different auxiliary gases need to be selected. The more common ones are: air, nitrogen, oxygen and argon.

1. Air

The air is directly provided by the air compressor. Compared with other auxiliary gases, the advantage is that the economic benefit is high and the air contains 20% oxygen, which can play a certain role in supporting combustion, but in terms of cutting efficiency, it is far less than oxygen as an auxiliary gas. High gas efficiency. After precision fiber laser cutting machine is cut with air assistance, a layer of oxide film will appear on the cut surface, which can prevent the coating film from falling off.

2. Nitrogen

Some metals use oxygen as an auxiliary gas when cutting, and an oxide film will appear for protection, while some metals need to use nitrogen as an auxiliary gas to avoid oxidation.

3. Oxygen

When oxygen is used as an auxiliary gas, most of the time when processing carbon steel, because the color of carbon steel itself is relatively dark, when steel cooper laser fiber cutting machine is cut with oxygen assistance, the surface of the workpiece will be oxidized and blackened.

4. Argon

Argon is an inert gas, and its main function is to prevent oxidation. The disadvantage is that the cost is relatively high.