There are five reasons for the poor machining accuracy of the vibrating knife cutting machine:

1. Line guide wheel radial runout or axial turbulence is larger;

2. There is a gap in the gear meshing;

3. The static torque of the stepping motor is too small, resulting in out of step;

4. The machining workpiece is deformed due to improper heat treatment of the material;

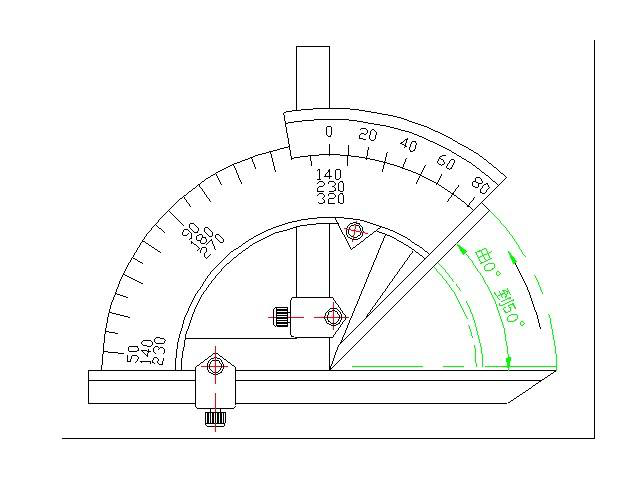

5. The cross table has poor verticality.

Vibration knife cutting machine solution:

1. Check the measurement guide wheel runout and turbulence error, tolerance: axial 0.005 mm, radial 0 002 mm, if it does not meet the requirements, need to adjust or replace the guide wheel and bearing;

2. Adjust the position of the stepping motor to eliminate the gear meshing clearance;

3. Check if the stepper motor and 24 V drive voltage are normal;

4. Select the workpiece material and heat treatment process;

5. Re-adjust the cross table.

Previous:

LXSHOW wait for you in Canton Fair

Previous:

LXSHOW wait for you in Canton Fair