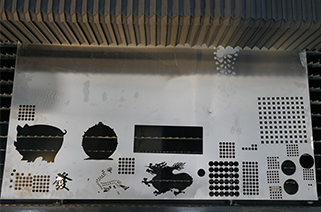

iron laser cutting machine processing carbon steel:

When oxygen is used as the auxiliary gas in the processing, the edge of the cut object will be slightly oxidized. Therefore, when the thickness of the workpiece reaches a certain level, in order to ensure the cutting effect, the critical value of the plate thickness of switching auxiliary gas is 4mm. When using nitrogen as the auxiliary gas, the cut edge of the workpiece is not easily oxidized. When the thickness of the cutting object of 3kw laser reaches 10mm or more, it is necessary to apply a unique pole plate to the 2kw laser cutter laser. In addition, there is a small trick: grease on the surface of the workpiece can have a positive effect on the cutting effect.

Copper and brass

When brass within 1mm is used as the workpiece to be processed, try to use nitrogen as the auxiliary gas for fiber laser cutter price;when copper within 2mm can directly cut copper and brass, the high reflectivity of the two types of materials is aimed at protecting the lens and Gas electronic components do not cause irreversible damage. However, if a "reflection absorption" device is installed on the raycus fiber laser 1000w system software, in this case copper and brass can be laser cut.

Cutting stainless steel

According to customer feedback, stainless steel is the most common processing object of 4kw laser cutting machine for sale. Stainless steel is widely used in various fields, including automobiles, airplanes, railway transportation, aerospace and other large precision machinery and equipment, as well as doors and windows, kitchen utensils and other daily necessities. In order to ensure that the finished stainless steel processing product is not oxidized and has no burrs, it is necessary to select nitrogen as the auxiliary gas of the fiber laser cutting machine.

Cutting aluminum

Like copper, aluminum also has high transmittance and good conductivity. Even so, 4000w laser cutting machine can still cut aluminum within 6mm. According to customer feedback, when oxygen is used as auxiliary gas for cutting, when cutting pure aluminum, it is necessary to install a "reflection absorption" device on the 500w fiber laser price system software and then perform laser cutting to protect the electron optics. , The surface is rough and hard. When using nitrogen, the cutting effect is very good, and the cutting edge is smooth. The components are not damaged.

iron laser cutting cutting titanium

Titanium plate cutting processing is not common, iron sheet laser cutting machine requires argon and nitrogen to assist cutting.

Previous:

LXSHOW wait for you in Canton Fair

Previous:

LXSHOW wait for you in Canton Fair