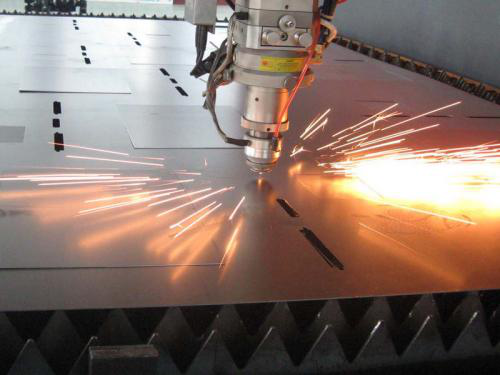

The fiber laser cutting machine is a laser beam that is emitted by a laser to a vertical downward laser beam through a 45° total reflection mirror, and then concentrated by a lens to form a small spot at the focus, and a laser that focuses at the spot. The power density is as high as 10^6~10^9W/cm^2.

The workpiece at its focus is illuminated by a high-power-density laser spot, which will generate a part of the high temperature above 10000 °C, causing the workpiece to vaporize in an instant, and then cooperate to assist the cutting gas to blow away the vaporized metal, thereby cutting through the workpiece. Into a small hole, with the movement of the CNC machine, countless small holes are connected to form a shape to be cut. Because the frequency of laser cutting is very high, each small hole joint is very lubricated, and the cut product has a high degree of finish.

Previous:

LXSHOW wait for you in Canton Fair

Previous:

LXSHOW wait for you in Canton Fair