As soon as tube laser cutting came out, it caused a huge sensation in the pipe processing industry and brought qualitative changes to all aspects of the pipe processing field. tube laser cutting services belongs to laser iron cutting machine and the main processing object is metal pipe.

On the whole, the economic benefits are 8-20 times that of traditional processing methods, mainly in the following aspects: cutting speed changes, pipe laser cut material reduction by more than 15%,saves a lot of labor costs and time, laser cutting fiber processing costs are reduced by at least 70%

Generally speaking, any technology that brings about major changes can be recognized by the broad market because of its excellent technical advantages. So what are the advantages of optical fiber laser cutting machine?

After importing the shape into the program, cnc laser metal cutter can cut any edited shape on the pipe, it is not restricted by direction. Compared with traditional cutting methods such as plasma cutting,it has minimal deformation during material processing.

It can be seen that laser power to cut metal can replace mechanical milling, milling, sawing, punching or cleaning of burrs and other processing procedures that require different metal pipe processing equipment and hard tools to realize cutting and chamfering of complex pipe structures. Cutting grooves or holes, nicks and other possible size and shape features processing, etc., can be widely laminated sheet metal processing, kitchenware, lamps, automobiles, medical equipment, hardware, fitness equipment and other industries.

As the demand for pipes in the market continues to grow, major manufacturers have increasingly higher requirements for pipes. The higher precision and high efficiency have become the first choice of pipe processing manufacturers, which has increasingly promoted further development.

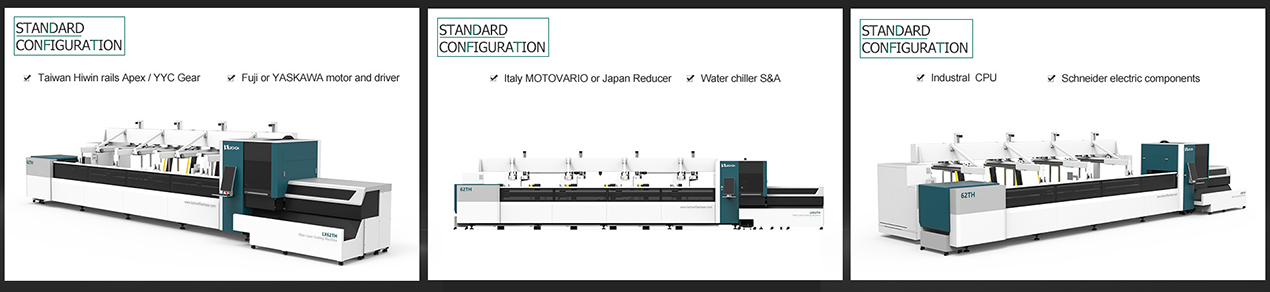

The needs of manufacturers will change over time and gradually change. The default design can be adjusted at any time according to the needs of customers.

cutting metal laser is equipped with automatic loading and unloading device, effectively reducing labor costs.